By now, Americans are pretty used to the idea of companies moving their operations overseas, but seeing foreign companies open up shop in the United States is less common.

Thanks to Governor Andrew Cuomo’s START-UP NY program, Windsor Wood—a carpentry business based in India that specializes in creating Windsor chairs—is expanding and moving a branch of its business to Syracuse. Partnering with the SUNY College of Environmental Science and Forestry (ESF), Windsor Wood USA will manufacture stronger and more resilient hardwood products, such as baseball bats, building materials, and interior car parts, using less desirable woods, such as hickory, white ash, and maple.

“START-UP NY provides companies with a number of tax-related benefits when they expand or relocate to the state,” said Joe Rufo, vice president for administration at ESF. “For example, the companies are exempt from paying property taxes, sales tax, and income tax for their employees for ten years.” In addition, he said, the companies partner with universities and set up their operations on or near university campuses.

According to Rufo, Windsor Wood USA and ESF are natural allies—they share an interest in conducting research on safe and sustainable wood products.

Stronger Hardwoods

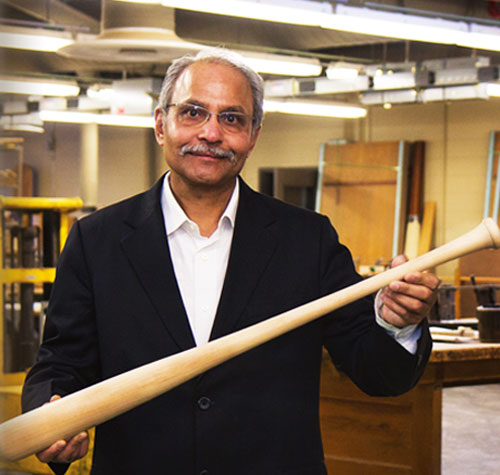

Prakash Suthar is a third-generation partner in his family’s carpentry business in India. For some 30 years, he has divided his time between that business and his other career as a tax and business advisor, first for Deloitte India and then for the federal government. In 2006, after many years of trial and error, Suthar, along with his brother and his son, created an eco-friendly process that renders various hardwood products virtually unbreakable and customizable. It was then that Suthar decided to devote himself full time to expanding his family’s company.

“The all-natural, no chemicals used, six-to-eight-step proprietary treatment process that we developed improves the microstructure of wood fibers,” said Suthar. “This process not only enhances the product’s durability, it also gives control over the hardness and softness, flexibility, and strength properties of the wood, and allows us to significantly increase the bending strength of North American hardwoods.”

According to Suthar, the treatment process can be used to prevent splintering of wooden baseball bats; to make wood-framed houses and commercial high-rise buildings more resistant to earthquakes and storms; and to produce high-quality interior car parts, high-heel shoes, and cabinetry for printers, copiers, and other electronic goods, among other products.

“Incorporating our wood products will reduce the building costs and sale prices of houses and commercial buildings, and will increase the value of what are currently low-commercial-value hardwoods in North America,” he said.

A Benefit to All

Suthar noted that his company stands to benefit a great deal from the move to Syracuse. “The quality of North American hardwoods is second to none in the world. The people there take great care of the trees; they treat them almost as if they are their children,” he said. “Establishing the main plant in New York will give us better access to these resources, which will save time and money and allows us to better penetrate the U.S. market.”

The company—which will set up in the Salina Industrial Plant, a former General Motors facility, sometime this summer—also will profit from its relationship with ESF. For example, it already has used the college’s testing equipment—equipment that would be cost prohibitive to purchase—to examine the characteristics of various wood billets and to investigate the amount of flexibility and strength in their wood products.

Rufo noted that ESF looks forward to the relationship with Windsor Wood USA as well. “We would like to partner with the company in terms of research, and we hope to establish a program in which some of our students can intern with Windsor Wood,” he said.

But the benefits extend beyond just the two organizations to include the entire community and even the state. “Many of the expert carpenters in New York are unemployed because their jobs have moved overseas,” said Suthar. “We are going to bring that work back for them. By year five, we hope to have created 100 new jobs. We also plan to train these new employees to perform our proprietary process of treating the wood and to manufacture wood products.” New manufacturing jobs, such as those that will be created by Windsor Wood USA, are less common among start-up companies, which usually focus on technology and the life sciences, and enable people with different skill sets to find work, he added.

According to Rufo, the effects of this job creation trickle down to people in the community who are not involved with the company. “People with good jobs buy houses, shop at local stores, and contribute to the local tax base,” said Rufo. “Windsor Wood’s move to Syracuse is a win-win for everyone.”