When Shenqiang Ren’s kids ask him what he does at work, the University at Buffalo engineer explains that he makes an impact by creating new materials that solve complex energy and environmental problems.

Working in the UB MAE/Chemistry/RENEW Lab, Ren has come up with a number of innovative solutions ranging from ecofriendly aerogel insulation and kirigami-inspired electronic circuits to a 2-D nanosheet that expands like a Grow Monster. His latest project aims to power the next generation of printable hybrid electronics.

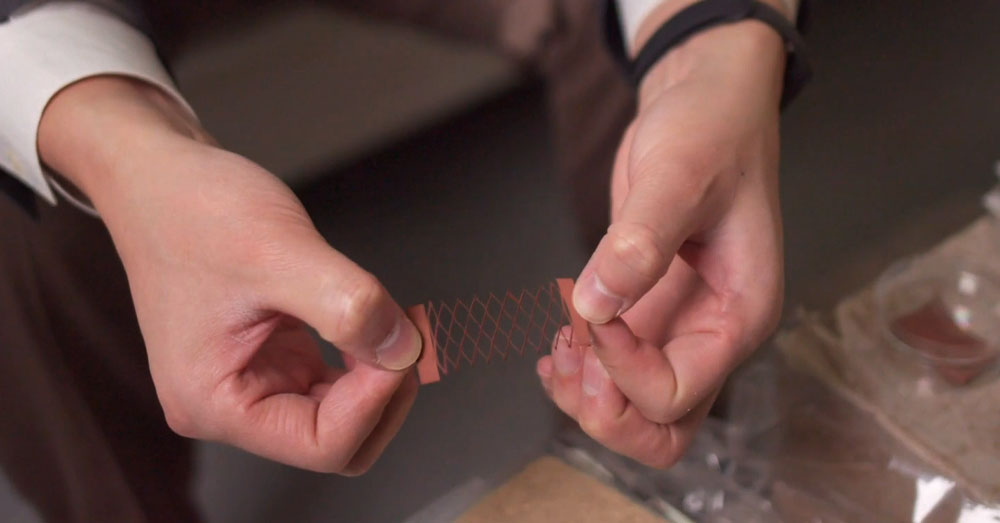

First, Ren and his research team created a copper-based conductor ink material that can operate at extreme temperatures of 1,000 degrees Celsius or more. Then they figured out how to use additive manufacturing – ink jet printer – to use the ink to print high temperature resistant circuits. Not only is this technology more efficient than traditional methods in terms of time and materials, it also makes electronics manufacturing more sustainable by eliminating waste and harmful chemicals.

With the help of a 2022 TAF investment, Ren and his research team are prototyping the new technology, which will lead to new applications in medical devices, the aerospace industry, robotics and more. “Our main focus is partnering with government agencies to make this available to the electronics manufacturing supply chain,” said Ren.

See how Shenquiang plans to make his work commercially viable thanks to TAF in the video below: