Protective equipment like face shields have become essential to medical personnel caring for patients with COVID-19. With its 3D printing technology, campuses at SUNY and the City University of New York are delivering thousands of face shields that are safeguarding the lives of our essential healthcare workers.

Healthcare workers at the frontline of the COVID-19 pandemic are receiving a welcome donation of face shields in coming weeks, as SUNY and the City University of New York join forces to manufacture these essential pieces of personal protective equipment (PPE).

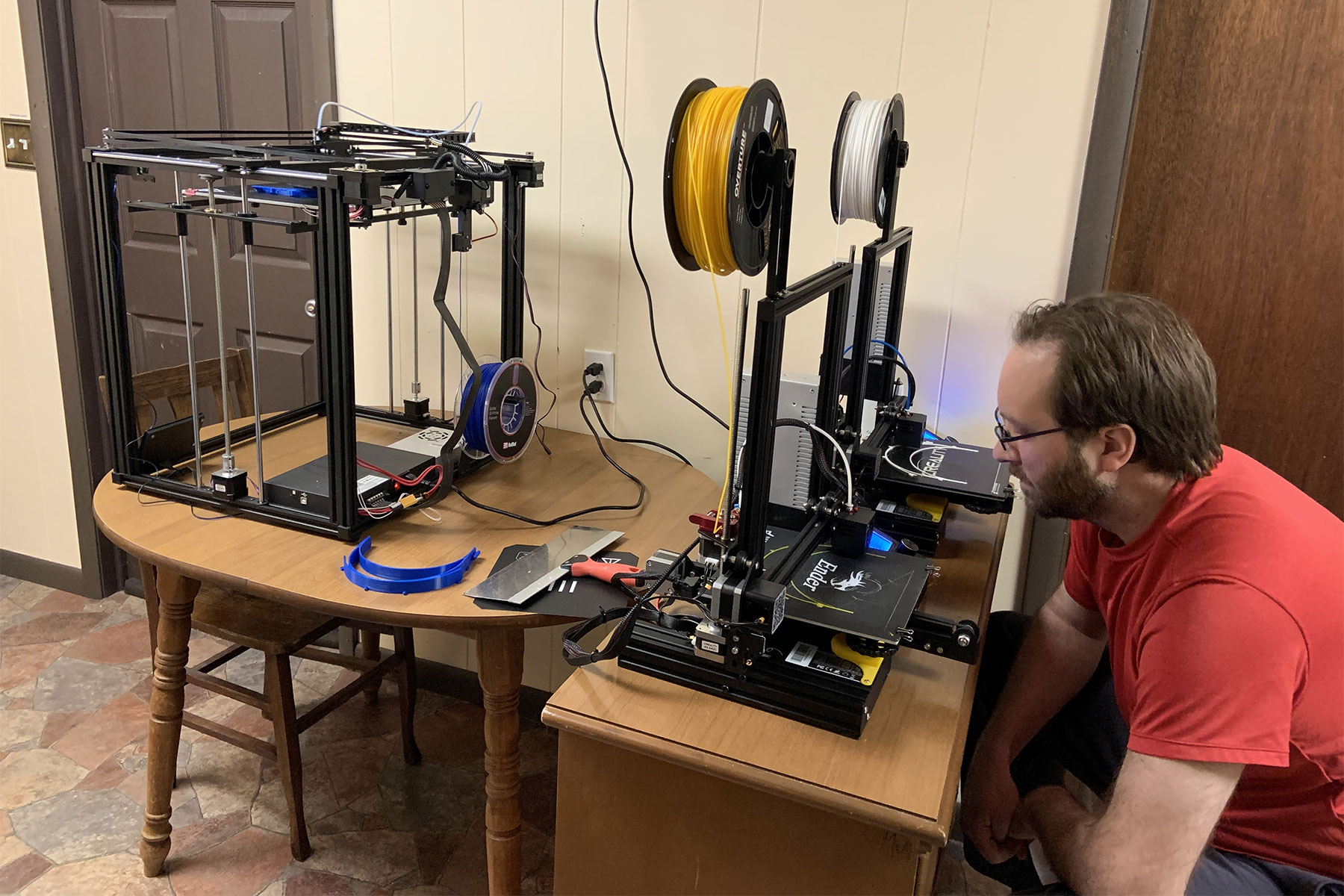

Nineteen SUNY campuses and six CUNY campuses will be manufacturing 2,400 face shields a day in the next two weeks. The manufacturing is made possible with 3D printing, an emerging technology that is providing an invaluable means for SUNY and CUNY campuses to assist in the battle against coronavirus.

The 3D printing process generates complex three-dimensional objects from computer-aided designs. Face shield manufacturing is expected to increase as more campuses receive materials for 3D production.

Why Shields are Necessary

Face shields are critical pieces of PPE worn by healthcare workers whenever they are at risk of infection, whether it’s filling a cavity in the dentist’s office or taking care of a patient with COVID-19. The shields are worn over masks to protect a provider’s eyes, nose and mouth from potentially infectious aerosol droplets produced by patients.

During the current pandemic, face shields and masks have been in short supply in many medical facilities, including SUNY Downstate Medical Center in Brooklyn, designated by Governor Cuomo as a COVID-19 only facility.

“There is a critical need for personal protective equipment that our frontline staff uses to provide quality patient care for those infected with COVID-19,” said Wayne J. Riley, M.D., President of SUNY Downstate Health Sciences University. “We are grateful for the efforts of SUNY and CUNY campuses working hard to produce face shields and appreciate their contributions to help protect healthcare professionals during this pandemic.”

Face shields made by SUNY and CUNY are being donated to medical teams across the state, in hospitals, nursing homes, and testing sites. Demand for face shields has increased as the number of patients with COVID-19 has surged, along with the growth in testing.

Kudos to Campuses

Across the state, 19 SUNY campuses involved in the effort are producing 2,100 face shields a day. The campuses are: University at Albany, Alfred State, Binghamton University, Broome Community College, University at Buffalo, Canton, Cobleskill, SUNY’s Cornell colleges, Delhi, Hudson Valley Community College, Jefferson Community College, New Paltz, Oneonta, Oswego, SUNY Polytechnic Institute, Plattsburgh, Potsdam, Stony Brook University, and Sullivan Community College.

“It’s been a humbling experience,” said David Ecker, director of the iCREATE department at Stony Brook University, where the face shields are being made. “I am not a medical professional and have no medical training, but being able to make these face shields feels good. We’re able to contribute to the larger effort of fighting COVID-19. From speaking to the team, I know that we all feel that by us each doing our part, we can work together to meet the challenge before us.”

Among the most prolific producers of face shields has been SUNY New Paltz, where the Hudson Valley Additive Manufacturing Center resides. The campus has helped to produce more than 7,100 face shields so far, and recently transitioned from 3-D printing technology to injection molding.

“The most important role we played in this was designing and quarterbacking the project,” says Dan Freedman, dean of the School of Science and Engineering and director of the HVAMC. “We went through nine design iterations in four days and then printed 400 and got them to the medical folks to make sure everything worked.”

Six CUNY colleges—The City College of New York, Bronx Community College, Queensborough Community College, LaGuardia Community College, New York City College of Technology, and The Graduate Center—were also involved in making the face shields. They adapted their 3D printers and associated materials to make elements used in face shields, which were donated to local hospitals.

The manufacturing of face shields is one more way SUNY is answering Governor Andrew Cuomo’s call for assistance in the COVID-19 pandemic. In addition, SUNY has converted facilities on Long Island into medical treatment centers, set up drive-through testing sites on campus, and dispatched medical volunteers to the hardest hit locations. SUNY is also conducting research on antivirals as potential treatments for COVID-19.

People in the North Country of New York who are interested in volunteering to print 3D medical devices can visit the Northern NY 3D Printing Network.

Staff at SUNY Poly made this video to show us how a face shield is made.

technology wins.